We're a trusted and established specialist GMP manufacturer providing aseptic fill and finish services for Antibody Drug Conjugates (ADCs).

Antibody-Drug Conjugates (ADCs) are one of the fastest growing classes of anticancer drugs. Comprising of a cytotoxic payload linked via a chemical linker to a mAb, they preferentially target cancer cell surface antigen(s). This specificity reduces systemic exposure and detrimental side effects. ADCs are complex molecules that require careful attention regarding their composition. The cytotoxic payload and therefore, linking of mAb and payload are key determinants of the safety and efficacy of ADCs

Dedicated facility for development and cGMP manufacturing of your Antibody-Drug Conjugates (ADCs), including polymer drug conjugate and monoclonal antibody-chelator conjugate. We are experts in small-scale commercial ADC manufacturing.

>150 mL ≤50L

≤3000 vial

Find out more about how we facilitate your ADC programs by accessing our Antibody Drug Conjugate capabilities sheet

Find out more about how we facilitate your ADC programs by accessing our Antibody Drug Conjugate capabilities sheet

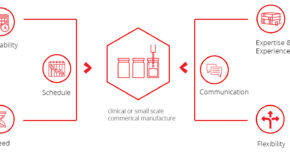

Symbiosis are the leading fast access CMO for clinical or small scale commercial manufacture and our offering is built upon the following principles:

Waiting 6 or even 12 months for a filling slot can be detrimental. We work to your schedule and strive to have availability in as little as 8 weeks.

Delivering your product to the clinic on time is essential, given patients are often waiting. Therefore, we execute over 90% of projects within the agreed timeframe.

We understand the need for results is a critical factor in the progression of clinical trials. Our typical fill-finish campaign takes 12 weeks.

Our dedicated team has handled >600 filling campaigns for mAbs to more challenging ATMPs for >100 customers. You are in safe hands.

Our service is underpinned by our expert project management team who will keep you informed every step of the way.

Drug development and manufacturing occurs in a dynamic environment. We work flexibly, where possible, to accommodate any changes that you may require.