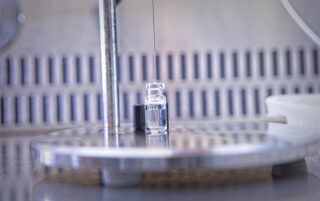

Biologic therapies often cannot be terminally sterilised and must be manufactured in an aseptic process. Symbiosis is fully licensed for the sterile filling of liquid and lyophilised investigational and commercial products.

Aseptic filling and manufacture is at the heart of what we do.

Production and purification of your bulk drug substance takes a lot of effort and time. However, consideration must also be given to how this drug will be delivered to the patient. Aseptic filling of sterile drugs remains one of the most critical processes in biopharmaceutical manufacturing Given the potential safety impact of parenteral administration, often in already compromised patients, aseptic fill and finish require stringent measures to ensure ultimate quality and safety.

Symbiosis has extensive experience in supporting therapy innovators with the complex process of aseptic filling into vials. We have helped many clients with a range of modalities from conventional small molecule, to cytotoxic, biologic and viral vector products.

We give you exactly what you need – rapid access to manufacturing slots and quick release of drug product to ensure that your tight timelines are met.

We specialise in liquid filling of vials at clinical and low volume commercial scale. We bring our flexible manufacturing approach to deliver your product within the tight timelines.